WHAT IS VACUUM BOTTLE INTERRUPTER?

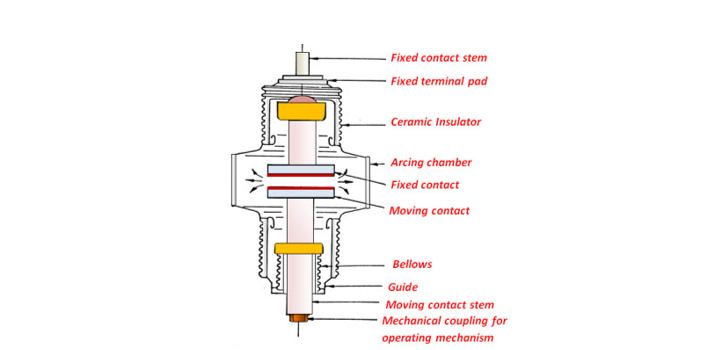

A vacuum circuit breaker is a kind of circuit breaker where the arc quenching takes place in vacuum medium. The operation of switching on and closing of current carrying contacts and interrelated arc interruption takes place in a vacuum chamber in the breaker which is called vacuum interrupter.

In electrical engineering, a vacuum interrupter or Vacuum Bottle is the core component of medium-voltage circuit-breakers, generator circuit-breakers & high-voltage circuit-breakers. Separation of the electrical contacts results in a metal vapour arc, which is quickly extinguished. Vacuum interrupters are widely used in utility power transmission systems, power generation unit, power distribution systems for railway, arc furnace application and Industrial plants.

Fig.1. Vacuum Interrupter

WHY DO WE TEST VACUUM BOTTLE INTERRUPTER?

Fast and reliable protection are the most important in case of any faults occurs in the electric power system. If the circuit breaker does not succeed in clearing the fault at the appropriate moment, the resulting accident can be dangerous in terms of both personnel injury and equipment damage and causing heavy losses.

Even though circuit breakers can be very reliable, they tend to gather dirt, moisture, and contaminants on the poles and on the exterior surface of the interrupter which may cause insecurity during operation, and once the air finds its way in the vacuum bottle and leakage starts to appear, the vacuum bottle becomes unreliable.

For the mentioned above reasons and more, vacuum bottle interrupter must be tested and maintained to ensure proper operation during electrical faults. Insulation integrity test is recommended by the manufacturers of circuit breakers and well documented in international test standards as IEC and IEEE.

HOW DO WE PERFORM VACUUM BOTTLE TEST?

Perform a vacuum bottle integrity (dielectric withstand voltage) test across each vacuum bottle with the switch in the open position in strict accordance with manufacturer’s published data.

We can test the integrity of vacuum interrupter using both DC and AC technology, but the latter requires a very high current due to the capacitance of the breaker which makes the AC test instruments quite massive and cumbersome. Besides, the use of AC technology did not add any additional information to the testing of the vacuum interrupter. For these reasons, DC testing technology is preferable to make an appropriate diagnosis of all possible sources of dielectric malfunction in circuit breaker vacuum bottle.

Testing high voltage circuit breakers present a series of challenges. HighTest’s knowledge and unrivalled experience within the power circuit breaker industry resulted in the VABO-80. This lightweight and impressive device tests vacuum bottles by applying DC high voltage up to 80 kV.

The HighTest Vacuum Bottle Tester VABO-80 presents a superior alternative to AC Hipot testing. VABO-80 has a user-friendly test procedure where Pass/Fail indicators on its screen indicate the test results. The procedure avoids unneeded misinterpretations based on normal fluctuations of stray currents. Those are mostly due to test environments variables such as relative humidity or polluted surfaces of the tested object. At-fault indication, just confirm it by a renewed test and reversed polarity.

A typical test of circuit breaker vacuum bottle by VABO-80 follows a simple sequence:

- Make sure that the tested object is secured and safe to work upon.

- Ground both, the test instrument (VABO-80) and tested vacuum bottle to the same point.

- Set the test voltage to the voltage nearest to the desired test voltage given in the circuit breaker manufacturers’ specification.

- Set the test duration and current threshold.

- Apply HIV test leads across the first phase vacuum bottle by pressing the “Start” command button after clicking on the “Start” icon on the VABO-80’s screen.

- Look the test results.

- You can now repeat the sequences for phase two and three.

If no evidence of distress or insulation failure is observed by the end of the total time of voltage application during the vacuum bottle integrity test, the test specimen is considered to have passed the test and VABO’s Pass indicator will confirm that ‘’Test Passed’’.

VABO-80B, 80 kV Vacuum Bottle Tester with built-in Battery & Printer

VABO-80B is designed using advanced engineering technology to test circuit-breaker vacuum bottles up to 80B kV DC. VABO-80 has fast, easy and accurate measurement features using its user-friendly software. VABO-80B is a battery-powered device (optional feature), which allows users to perform tests even without power supply during field tests.

VABO-80, 80 kV Vacuum Bottle Tester with built-in Printer

VABO-80 is designed using advanced engineering technology to test circuit-breaker vacuum bottles up to 80 kV DC. VABO-80 has fast, easy and accurate measurement features using its user-friendly software. VABO-80 is a battery-powered device (optional feature), which allows users to perform tests even without power supply during field tests.